Pre-engineered buildings (PEBs) are a type of structure that is designed,

engineered, and fabricated in a factory setting before being shipped to the

construction site for assembly. They are a popular choice for a range of

applications due to their efficiency and cost-effectiveness. Here’s a detailed

look at pre-engineered buildings:

KEY POINTS ABOUT PEB

Pre-Engineered Buildings (PEBs) are made up of:

1 . Structural Frames: Usually made from steel, these frames provide the primary

support for the building

2. Secondary Members: Includes supports, purlins, and girts that add stability

and support to the building.

3. Roofing and Wall Panels: Pre-fabricated panels that can include insulation

and are designed to fit together seamlessly.

4. Accessories: Such as doors, windows, ventilation systems, and other

functional components.

ADVANTAGES

1. Faster Construction Time:

2. Cost Efficiency:

3. High Quality and Consistency:

4. Ease of expansion and modification warranty on PEB (upto 20 years)

5. Flexibility and Adaptability:

6. Sustainability

:7. Improved Project Management:

8. Less Site Disruption:

9. Enhanced Energy Efficiency:

10. Predictable Costs:

Applications

1. Industrial Facilities: Factories, warehouses, and distribution centers.

2. Commercial Buildings: Retail stores, showrooms, and office buildings.

3. Agricultural Structures: Barns, storage facilities, and processing units.

4. Recreational Facilities: Sports arenas, gymnasiums, and community centers.

Our Projects

SARVOTTAM MARBLES

FORACE POLYMERS

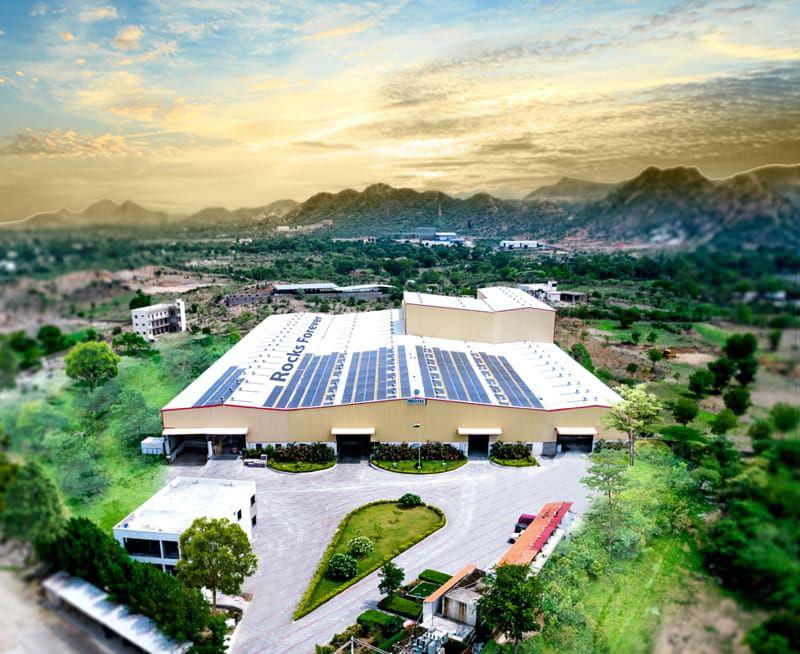

ROCKS FOREVER

GAYATRI SANDS

MAHAVIR STONE